The innovative, cold-rolled forming process ensures an ideal groove profile. The inherent elasticity and resilience of steel makes for a tougher sheave to meet the most demanding applications.

Stainless steel options available, click here.

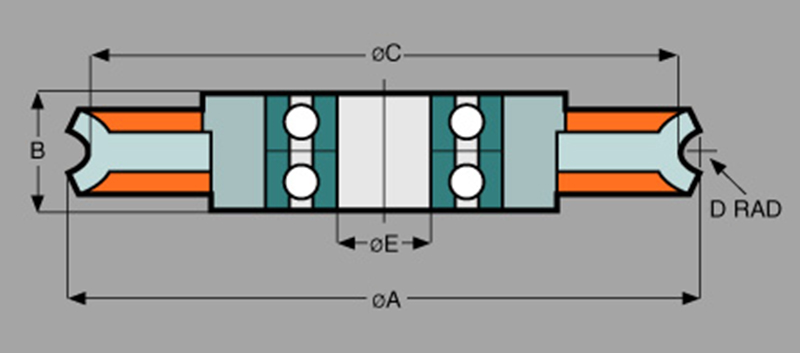

At Jeamar all of our steel sheaves are designed with a minimum arc of support for the rope of 125 degrees, ensuring that the rope cross sectional shape is maintained under normal load conditions. In turn, this increases rope life by minimizing internal rope flexing and increases sheave life by reducing gouging. Note: It is essential that the correct size of sheave be used for the rope. For instance, a 1/2 in. diameter rope should be used with a sheave that has a 1/2 in. groove radius, to achieve optimum conditions.

The ball and roller bearings are sealed and lifetime lubricated for long life and minimum maintenance costs.

Our premium steel sheaves incorporate either ball or taper roller bearings for maximum efficiency, reduced friction, smooth motion, long life and high speed.

Jeamar sheaves have a minimum sheave-to-rope ratio of 15:1. This ensures a large radius for the rope to bend around, which in turn decreases flexing of the rope and substantially increases rope life.

The strength of the steel used considerably exceeds that of cast iron. Steel also has a weight-saving advantage of up to 50 percent over cast iron, resulting in easier handling and installation.

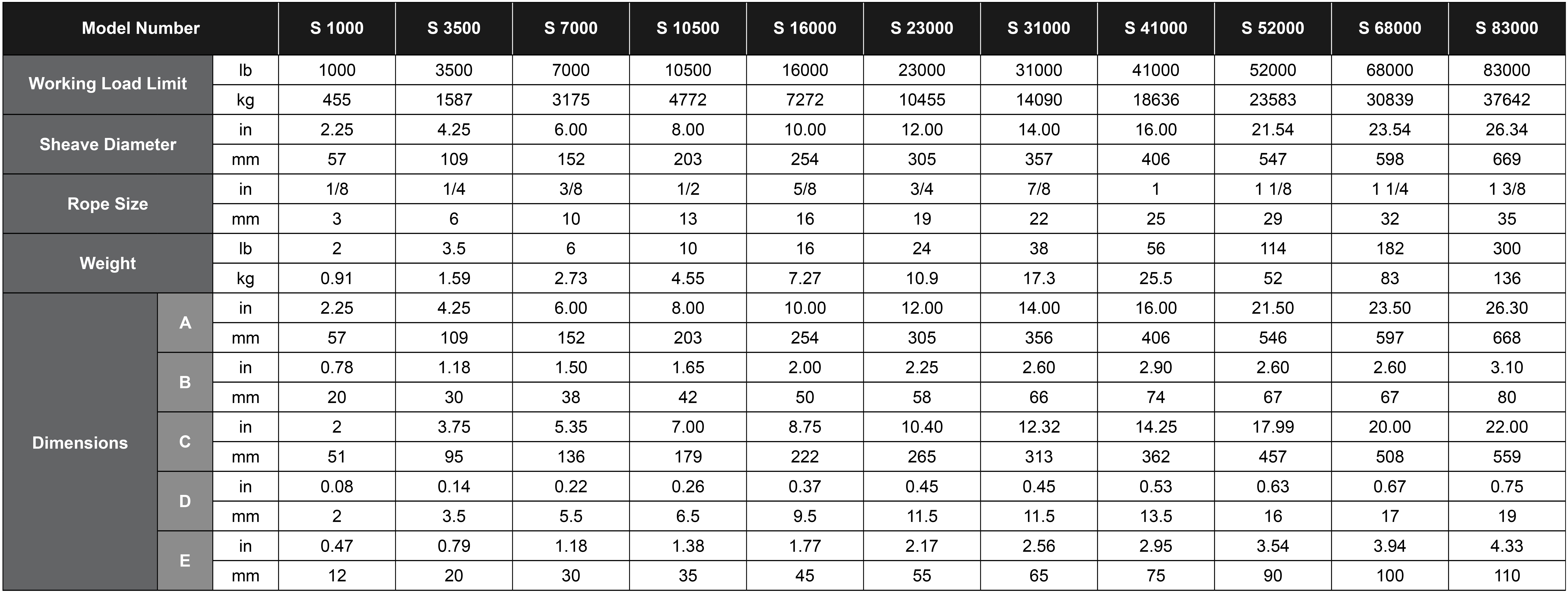

It is essential that the correct size of sheave be used for the rope. For instance, a 1/4 inch diameter rope should be used with a sheave that has a 1/4 inch groove, to achieve optimum conditions.

Due to our policy of continuing development, all specifications are subject to change without notice. Users of these products are responsible for ensuring their suitability for the application in which they are being used.